have you ever wondered what materials are used to create a solar panel? We just stick these magic panels on our roofs, and then they go to work making free electricity for us. Of course, plenty of cutting-edge technology and some clever engineering go into making it all possible.

I decided to find out some more and dig down into some real detail about what goes into our solar panels. I have some pretty definitive answers, which I’ll share with you here in my solar panel material list.

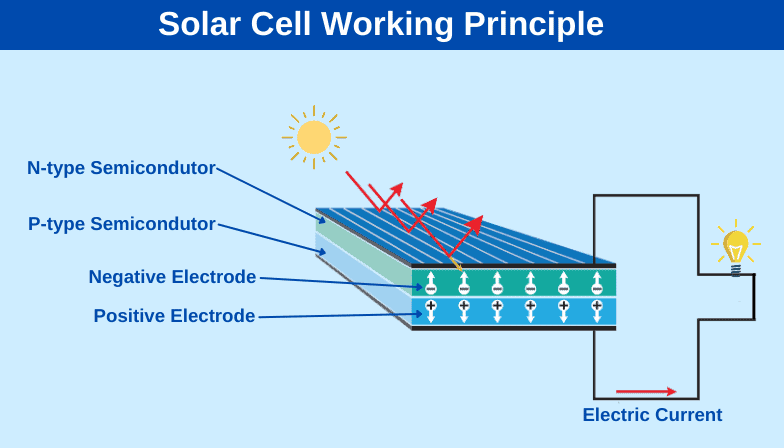

A quick recap of how solar panels work

The sun emits a vast amount of energy in the form of photons. These are elementary particles that represent a quantum of light and carry energy to Earth, contributing to heat, light, and radiation. Solar cells convert light energy into electrical energy by using something called the photovoltaic effect.

Each of our domestic solar panels is made up of sixty or seventy-two photovoltaic cells, and each of these is an individual solar energy converter. Inside each photovoltaic cell are two discs of differently charged silicon sandwiched together in a way that forms an electrical field.

When photons from the sun hit these silicon discs, a reaction breaks free of tiny particles called electrons. Electrons carry an electrical charge and these are what produce the flow of electricity that we harvest and convert for home use.

Solar panel composition

Now that we know how the process works we have an idea of what we need to make a working solar panel. For a start, we need a silicon-based photovoltaic cell.

Then, of course, we need something to house and protect the solar cell. And since we have several of these cells in each solar panel, we’ll need a substrate and frame to connect everything.

Finally, we need to do something with all the electricity we generate so there must be a cabling to connect all the cells and to transport the electricity so we can use it.

Now let’s list and examine each of the parts of your solar panel and look at the materials used to construct it.

This is an interesting video If you’re interested in the exact science behind the materials used for solar panels.

Solar cell

The silicon we use in solar panels is in a crystalline silicon (c-Si) form. Silicon is an element that fills the needs of a solar cell because it is a semiconductor. In other words, it’s a material that conducts electricity a little bit.

The semiconductive nature of silicon, meaning it can control an electrical current, is the reason it’s used extensively in the manufacture of electronic devices like transistors, diodes, and electrical circuits.

Silicon is one of the most abundant elements on Earth. We get it by mining rocks containing silicon compounds and then going through a complicated process to break this raw material down into pure crystalline silicon.

After separating, the silicon is processed and sliced into super-thin discs using a precise diamond saw. But it’s still not ready to go into our solar panel until it goes through the process of doping.

Doping is a complex process that applies an electrical charge to each side of the silicon wafer so that the top side has a positive charge and the bottom side has a negative charge. It is the electrical field created by these charges that drives the photovoltaic process and produces electricity from our solar panels.

Here’s a good article that gives you more information on the exact science of silicon processing.

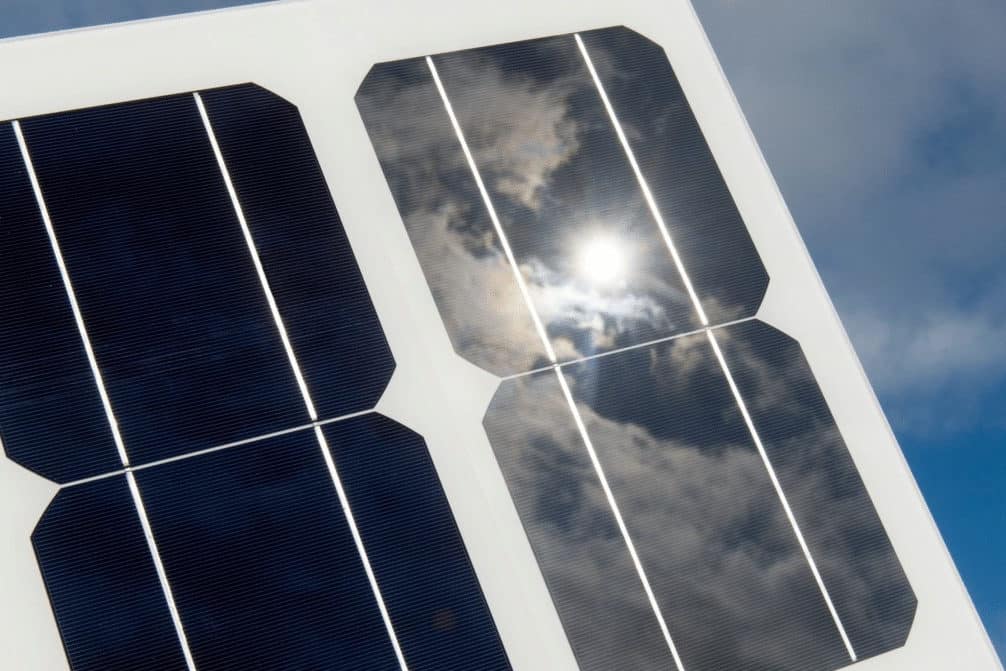

Anti-reflective coatings

Reflection is the enemy of solar panels since any light that gets reflected away from the panel can’t be absorbed and converted to power. That’s why your solar panels have a matt rather than a gloss appearance.

To complete a solar cell, a thin layer of an anti-reflective coating is applied. This coating reduces reflection and gives silicon cells their recognizable bluish tint.

Silicon nitride is the most commonly used anti-reflective coating in domestic solar panels.

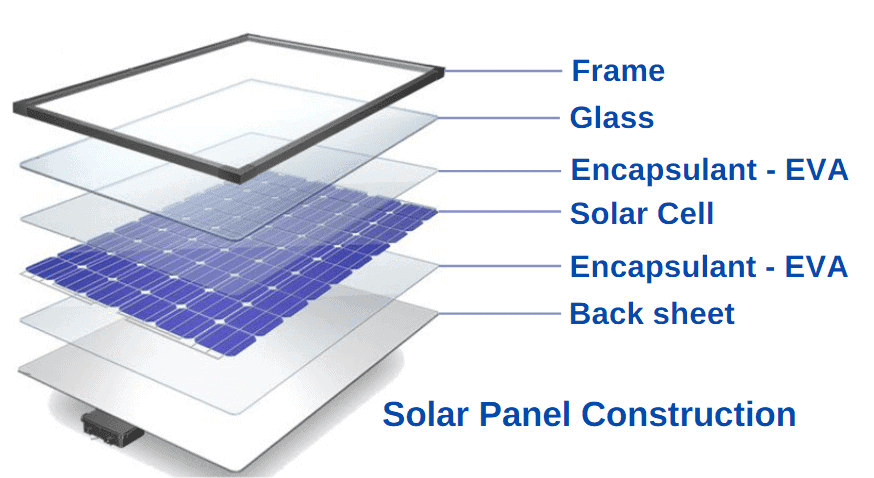

Sealing the solar cell

A completed solar cell must be sealed for protection. The compounds that are most commonly used to enclose solar cells are silicon rubber or ethylene-vinyl acetate. Silicon rubber is an elastomer or rubber-like material. It’s made by combining silicon with carbon, oxygen, and hydrogen.

Silicon rubber is used widely in industry. The silicon sealant you use around the home is the same stuff. This compound is perfect for encapsulating solar panels because it is not reactive and is resistant to very high temperatures. It is also transparent which is essential to allow the cells to receive the maximum sunlight.

Ethylene-vinyl acetate or PEVA is a synthetic polymer with similar properties to silicon rubber and is a good alternative material used to seal solar cells.

Putting the Solar Cells Together

now that we’ve assembled all the components of our solar cells, we need to gather them together into our solar panel using materials durable enough to allow it to operate for its expected lifetime of around twenty-five years.

Backsheet

sealed solar cells are next gathered together onto a back sheet. This supporting structure is typically made of Mylar or Tedlar.

Tedlar is another name for the polymer polyvinyl fluoride, and mylar is short for the polyester material (take a deep breath) biaxially-oriented polyethylene terephthalate.

These are both synthetically produced materials with unique properties that make them perfect for providing the backbone of the solar panel. They are highly resistant to weathering and also to extreme temperatures.

Frame

solar panels have a metal frame. Given that a solar panel couldn’t really be in a more exposed position, it’s vital to use a non-corrosive and robust material for the frame. Metal fits the bill nicely but it’s essential to use a metal that doesn’t corrode under rainfall and is unlikely to be harmed by dust and other foreign materials.

It’s also important that the solar panels frame isn’t too heavy since weight is a factor given that they need to be light enough for the roof of your house.

The metal that best fits all of these criteria is aluminum.

The Surface of the solar panel

If a solar panel gets cracked or broken, it’s important to know that a sheet of glass covers the panel’s front face.

A special kind of toughened glass, known as tempered glass, is used for the job. Tempered glass is the perfect material for the job because it is 4-5 times stronger than regular glass, providing the panel with a strong and durable protective cover.

Tempered glass is also good for safety because when it breaks, it doesn’t produce dangerous jagged shards like conventional glass. Instead, the tempered glass breaks into much smaller and safer pieces. This is very important if a rooftop solar panel is damaged and broken glass falls to the ground below.

Tempered glass is produced by an industrial process where regular glass is rapidly heated and cooled several times, increasing its strength.

Solar cables

Solar panels aren’t of any use if we don’t have a way to gather and transfer out the electricity they generate. So all solar panels need cables to do this job.

Aluminum and copper are the materials used to make cables for solar panels are. Aluminum is the cheaper of the two metals. It’s not as strong as copper and doesn’t conduct electrical current as well, so better solar panels use copper cabling.

As with all cables, the metal cable needs to be protected by an outer plastic layer. Since solar panels are located in an outdoor position and received lots of rainfall and high temperatures, their plastic coating is made from super-tough moisture and heat-resistant thermoplastic (THWN). Solar Panel manufacturers must meet strict guidelines on the type of insulation that they use for solar panel cabling.

Summary List of materials in a solar panel

So after all of that detail, we can write down a solar panel material list.

- Solar cell – Crystalline silicon (c-si), Silicon Nitride

- Solar Cell Sealant – Silicon Rubber Or Ethylene-Vinyl Acetate

- Backsheet – Mylar Or Tedlar

- Frame – Aluminum

- Cover -Glass

- Cabling – Aluminum Or Copper, Moisture And Heat Resistant Thermoplastic

Note that this is a list of the components that make up domestic solar panels. Some commercial solar panels operate in a slightly different way and are manufactured from other materials.

It’s also important to note that solar technology is advancing all the time. Shortly, we may not need to rely so much on silicon for solar panels since other semiconductors show great promise. Here’s a good video looking at some prospective new solar technologies.

We welcome your questions or comments about this article on the materials that make up solar panels.